GFRC has state-of-the-art research facilities both in Doha, Qatar, and College Station, Texas, that promote the detailed investigation of gas mixtures and complex fluids from the molecular all the way to macroscopic level. In this way, fundamental understanding of the properties of these systems is possible, allowing for optimum design of industrial processes and of improved final products. Some of these research facilities include:

At Doha, Qatar

- Novel High Pressure – High Temperature Fischer Tropsch Reactor Unit for studies at supercritical conditions.

- Fuel Characterization Lab with state of the art analytical equipment.

- Applied Catalysis Lab with high pressure fixed bed reactors, a slurry reactor unit, several gas chromatographs, various spectrometers (FTIR, Raman, quadrupole mass), simultaneous TGA/DSC unit, and BET surface area analyzer.

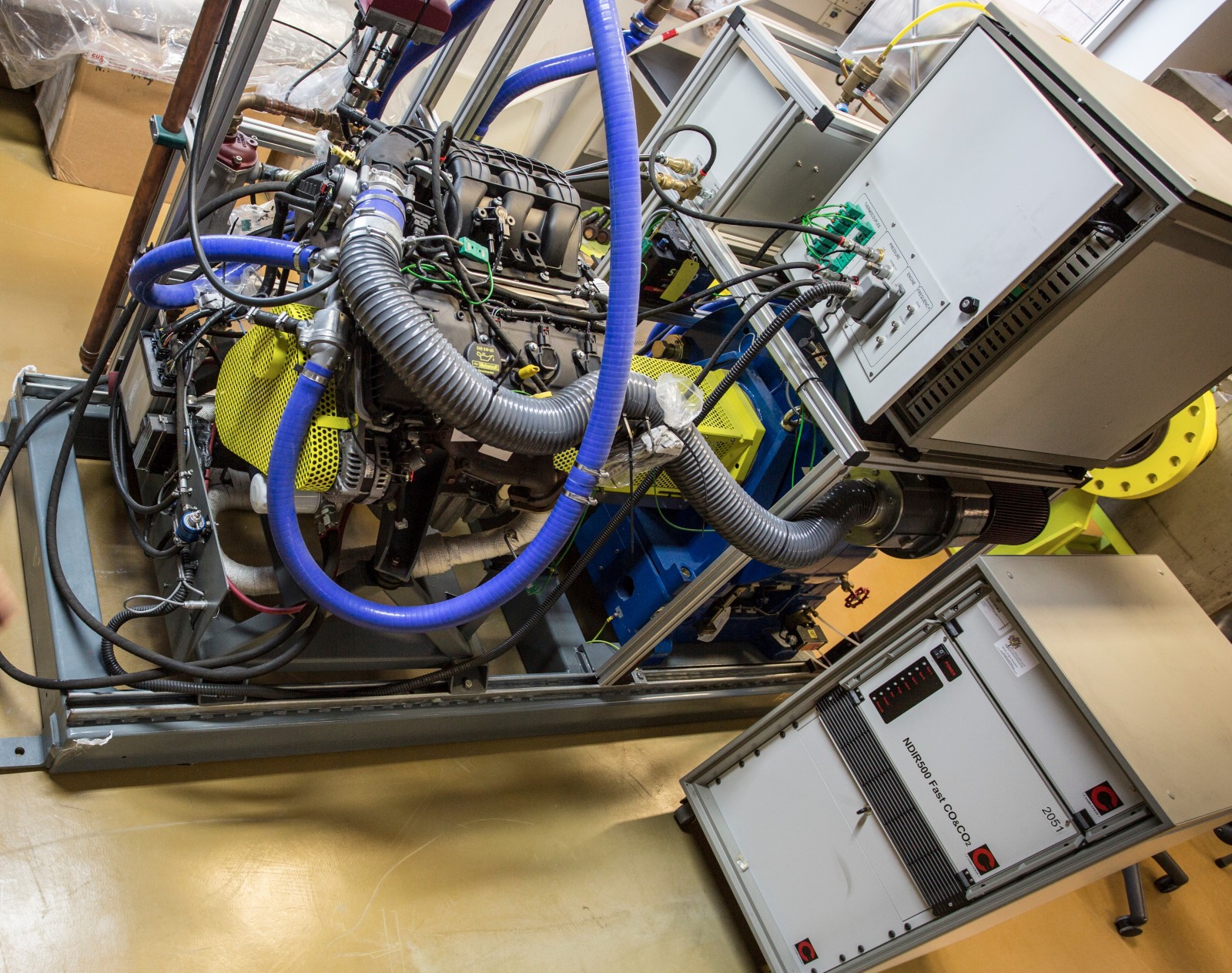

- Engine Research and Testing Laboratory equipped with various gasoline and diesel engines, and sophisticated data acquisition and analyzer systems.

- The Raad high-performance computing facility that consists of 2,208 CPU cores with an aggregate system memory of 9,000 GB and a peak performance of 42+ Tflops.

At College Station, Texas

- A 43-meter long vertical loop for the study of the upward flow of gas-liquid mixture under conditions similar to the ones in a natural gas producing well affected by liquid loading.

- Several analytical instruments that include HPLC, GC, temperature-controlled incubators, centrifuges, refrigerator/freezers, drying ovens, pH meters, biomass grinders, water baths, Rotovaps, Soxhlet extractors, and specialized pretreatment reactors.

- A pilot-scale fermentation facility.

- Combustion, Reaction and Characterization Lab with a scanning mobility particle sizer (SMPS) with condensation particle counter (CPC); a Hiden Catlab powder reactor system; a custom built two-stage powder reactor monitored by mass spectrometer; we are in the progress of finalizing a custom built bench scale core reactor monitored by FTIR.

- Chemical Reaction Engineering laboratory for manufacturing and testing catalytic packed-bed reactors and membrane reactors, as well as analysis of permselective membrane materials via variable-pressure, constant-volume and Wilke-Kallenbach (constant pressure) permeation apparatus. The laboratory is also home to a suite of materials processing equipment for synthesizing ceramics and performing electrochemical analysis of solid-oxide electrolyte materials.

- The Brazos computing cluster with 311 computing nodes with various processors with a total memory of 9,300 GB and total peak performance of about 28.1 Tflops.

- Large amount of in-house developed and commercial simulation codes for the analysis, design, and optimization of various gas and fuel processes.

In all cases, the facilities are operated by experienced technicians and post-docs while graduate students are actively involved in relevant experimental and computational projects.